-

Posts

305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

FAQ

Tests

Classifieds

Store

Group Buys

Posts posted by Xstiffshafts

-

-

Well i finally started an arc, pool, and laid a bead (although it's ugly as sin) I got two pieces of scrap metal welded together. Gonna have to put a few hours in before I try to do this to a putter

Sent from my iPhone using MyGolfSpy

-

I picked up the equipment over the course of this last week. Got a 125a stick welder and jiggered together a welding table. Spent the first two nights not understanding why I'd trip the breaker every time I got an arc struck. So I'm in process of moving rig to draw from a 20 amp circuit, but definitely still have some questions.

Sidenote: this was a sneaky expensive attempt at fixing the necks on two Camerons that I snapped off.

Sent from my iPhone using MyGolfSpy

-

I need some help. Do any of you guys who've been active in the thread know how to stick weld?

@mcaseym

@aliens8mycow

@ballenbrandon

@fozcycle

@cnosil

+anyone else who may be able to help a total welding n00b

Sent from my iPhone using MyGolfSpy

-

-

This is a roundback I've been tinkering with this week, and finally settled on colors for.

Sent from my iPhone using MyGolfSpy

-

One of the '16 Newport 2's done for a buddy's daughter who plays high school golf.

Sent from my iPhone using MyGolfSpy

-

I have a grinder now as well, but in the beginning it was all hand sanding all the time

Sent from my iPhone using MyGolfSpy

-

After sanding is done... I'll move on to polishing most of the time. I prefer flitz polish which can be bought on amazon, but in a pinch I've used the white diamond stuff from wal-mart and it works just fine. Hand polishing with a microfiber cloth is sufficient, and the shinier you get it, the more color you're going to see from torching. Some of my favorite work has been from slowly working polish all over the putter until it's "mirrored".

When you're done here, it's time to clean the head for torching.

Sent from my iPhone using MyGolfSpy

- Ballenbrandon, McaseyM, downlowkey and 1 other

-

4

4

-

I think it's better to do everything by hand for the most part. I've used dremel in past to try to make the work go faster and it's too easy to nick the collet on the putter, etc...

Sent from my iPhone using MyGolfSpy

-

@ballenbrandon sure!

Prep is everything - it's the difference between a good/great job for sure. I'm impatient as they come, so it's hard for me to prep the right way, but it's worth it.

Sanding:

You'll want to start with ~120 grit and work the putter until you've gotten a majority of the dings/dents/scratches out. If it has really deep dents, hand filing before sanding isn't a bad idea. Then you move up to 400 grit, and repeat with 1,000 grit (1 dry/1 wet), then 2,000 grit (1dry)

Wear some gloves while you sand. It's nasty.

Sent from my iPhone using MyGolfSpy

- cnosil, Thatginger96, Ballenbrandon and 1 other

-

4

4

-

Hahahahaha @aliens8mycow that's hilarious. Onto the putter, I know the color you're referencing and love it, I tried to nail it and missed with a studio Select Newport 2 mid slant a few months ago. That yes looks fantastic, work very well done!

Sent from my iPhone using MyGolfSpy

-

I worked on a Toulon San Diego on Monday... I thought it turned out pretty well...this is a buddy's putter who had the cool idea of blasting everything but the face milling and going for a high polish on it.

Sent from my iPhone using MyGolfSpy

- Ballenbrandon, McaseyM, Thatginger96 and 1 other

-

4

4

-

I also like the raw look. Sometimes I love the way a putter looks after being sandblasted too. I usually don't stop there, but the face on that thing looks great.

Is that yes stainless or carbon? I think it's stainless bc you wouldn't leave it raw if it were carbon and it was rusting due to just the little bit humidity in the house - carbon has a biiig color spectrum when torching... even still, I bet that thing would look great Torched really dark.

Sent from my iPhone using MyGolfSpy

-

-

-

I really like some of the darker torched colors. Some really neat finish colors can be achieved, especially on carbon steel.

Here's the rest of that notch

Sent from my iPhone using MyGolfSpy

- MDGolfHacker, Thatginger96, fozcycle and 1 other

-

4

4

-

Here's a preview of the one I'm about to finish. Will probably take a break over the weekend and just chill. Looking back, I ripped 'em out at a pretty rapid clip this week.

Sent from my iPhone using MyGolfSpy

- Ballenbrandon, Thatginger96, McaseyM and 1 other

-

4

4

-

Thanks @thatginger96

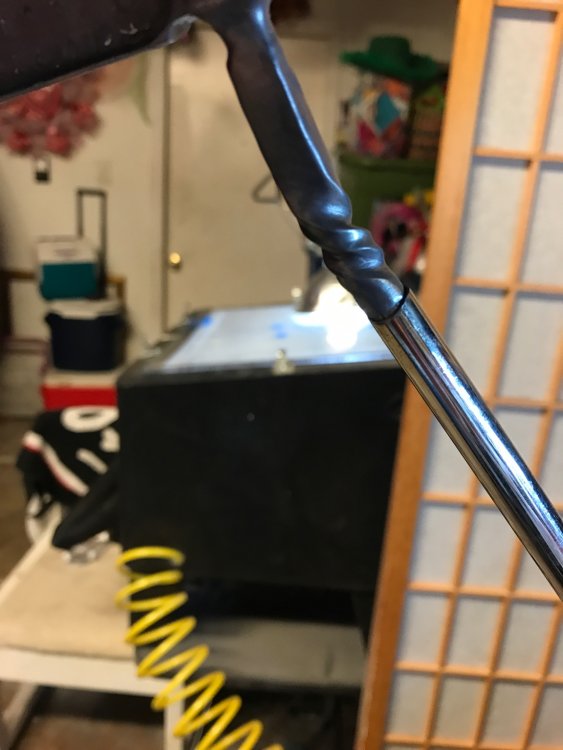

The twisted neck was a lot of fun to do, and I can see why people get addicted to making crazy neck designs.

It was a little flat (if a little is like 9°), so I heated again and bent it back to within a couple degrees +/- of 71°. When I say I bricked this putter, I really mangled it. It was like the 2nd-3rd putter I worked on and started with the bench grinder before I knew what I was doing... thankfully it was mine. Earlier this week, I ended up totally reshaping the putter with the bench grinder, grinder, file, etc... to give you about idea, "BETTINARDI" in electric green in the cavity is no longer there. The face milling fades from the heel toward the toe as well --- so it was a safe head to try the twist on. Would love to do a plumbers neck next.

@mcaseym - it's actually carbon steel at about the darkest a torch will get it - it looks black in hand. No corrosion protection though.

Sent from my iPhone using MyGolfSpy

-

I could not resist this Machine M2A Converter. It is so damn slick. Billings has such genius work and does some incredible finishing on his pieces. Gaming this bad boy.

Sent from my iPhone using MyGolfSpy

- Thatginger96, McaseyM and fozcycle

-

3

3

-

Just gave my first twisted neck a go on a Bettinardi BB1f that I bricked early on in my foray into torching/refinishing.

Sent from my iPhone using MyGolfSpy

-

Thanks. That M2 is purple/grey but I blasted it after torching, so it definitely lost some of its color.

Here's its cousin, the M1:

Sent from my iPhone using MyGolfSpy

-

The latest and (hopefully) final M2, which I just finished for a buddy.

Sent from my iPhone using MyGolfSpy

-

Here are pics with a little more sun.

I'm definitely pleased with the finish, I'm not sure I love the different colored sole weights, so silver may become blue... this one is destined to be sold, planning to list on eBay. If anyone is interested in a little MGS discount, PM me... I always loved the way Monterreys looked, but never putted well with one.

Sent from my iPhone using MyGolfSpy

-

Here's a Monterrey that was beadblasted prior to torching. I'm absolutely digging the ability to retain the color(s) achieved thru torching, and still have a solid, professional-looking satin finish.

The toe weight is drying (not missing).

It's cloudy and crummy today, it'll be nice to take a few pics on a sunny day bc this thing is an even purple/blue all over.

Sent from my iPhone using MyGolfSpy

Member DIY Club Restores/Refurbs/Refinishes

in Club Making/Repair & DIY Projects

Posted

I have a closet full of old putters in fact I just got a piece of rebar welded to where the neck used to start on a beat up old anser... it's ugly as hell tho, starts/stops, slag everywhere

Sent from my iPhone using MyGolfSpy