-

Posts

198 -

Joined

-

Last visited

About dbdors

- Birthday 06/11/1960

Contact Methods

-

Twitter

none

-

Instagram

none

Profile Information

-

Gender

Male

-

Location

Houston, Tx (Clear Lake Area)

-

Referred By:

Web

Player Profile

-

Age

60 and over

-

Swing Speed

91-100 mph

-

Handicap

12

-

Frequency of Play/Practice

Multiple times per week

-

Player Type

Casual

-

Biggest Strength

Approach

-

Biggest Weakness

Driver/Off the Tee

-

Fitted for Clubs

Yes

Recent Profile Visitors

3,463 profile views

dbdors's Achievements

(1/14)

211

Reputation

-

12, if I loose that many before 18 I'm going home anyway!!!

-

What Have You Built Recently?

dbdors replied to GolfSpy_APH's topic in Club Making/Repair & DIY Projects

I always like his video's -

Any tips for someone looking to regrip their own clubs

dbdors replied to jayyarr's topic in Club Making/Repair & DIY Projects

I always used a heat gun and it was still a pain. I just hated it. -

Any tips for someone looking to regrip their own clubs

dbdors replied to jayyarr's topic in Club Making/Repair & DIY Projects

This is the part that I hated so much!! Doing that 13 times just made me crazy. This is one of the main reasons I switched to blowing them on. -

Any tips for someone looking to regrip their own clubs

dbdors replied to jayyarr's topic in Club Making/Repair & DIY Projects

I play MCC+4 and have not had any issues with twisting. I do use 2 layers of build up tape. And it's not a thin tape. I know that some mention using blue painters tape. From my checking, the blue and plain masking tape seems to range from 4 to 5 mill thick. The stuff I use from GW is 7.5 mil, and I use two layers. -

Any tips for someone looking to regrip their own clubs

dbdors replied to jayyarr's topic in Club Making/Repair & DIY Projects

You don't need a big expensive compressor. A simple tire inflator will work. Or a cheap harbor freight compressor. I have a large compressor for woodworking, etc. But I have this one that I use at boat storage for tires. https://www.harborfreight.com/air-tools-compressors/air-compressors-tanks/3-gallon-13-hp-110-psi-oil-free-hot-dog-air-compressor-57572.html It will do the job for grip for sure. They go on sale from time to time. And I got mine in the bargain bin for $30 I believe. It just has a leaking fitting. A little Teflon tape and it was fixed. I like blow on for the simplicity to remove and install. I used solvent for years. I finally got sick of removing the old double sided tape each time I needed new grips. Or If I needed to work on a club and reuse the grip (did this often trying various putter grips. It is just so much easier. I can blow off a grip and add a second layer of build up tape and test it out. If I don't like it, I can blow it off, remove the tape and put it back on. -

I tried a set once, still have 3 left. Didn't wear it long enough to check durability. I just find them to be undersized and overly tight. I wear XL and these were tight and uncomfortable. I lost if mid round some where (maybe a subconscious, "get rid of this glove" move) and threw the other 3 in the closet. I also found the Costco gloves to be undersized as well and have not tried them again either. The best low cost glove that I have found are the MaxFli Tour Glove. They can be had for $20 for 2. Not too bad a price.

-

Hey all you DF3 owners. I need a favor. I'm still waiting on my putter to finish production and deliver. In the mean time I'm looking at some alternative head covers. Would anyone of you with a DF3 mind measuring the overall dimensions of the head. Basically the "face width", "face thickness", "depth from face to back" and finally "face to center of shaft" Thanks in advance!

-

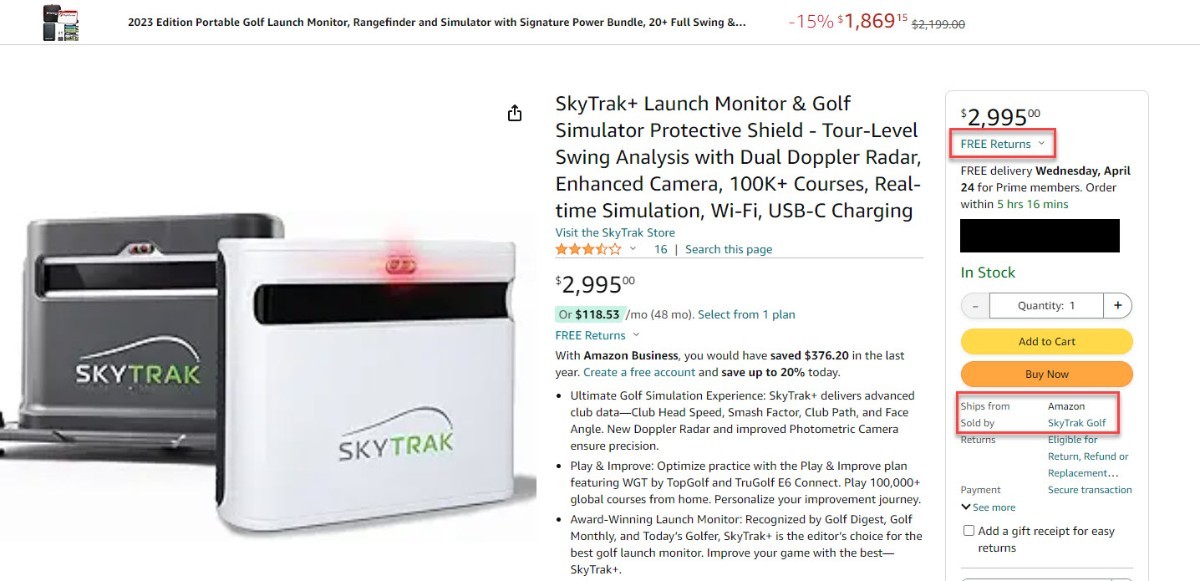

I only see 2 listing for this with the protector on Amazon. They both are the same. "Ships from Amazon" , "Sold by SkyTrak Golf" and "Free Returns". Sometimes what suppliers send to Amazon may be missing something, stuff happens, nobody's perfect. But the situation is still the same, pack it up and submit a return. Take it to your local Kohls, UPS or whatever options you have and send it back. The refund will be processed within a day at worst. Or you can submit it as an exchange. Send it back and they'll send a replacement. For the most part Amazon is pretty easy to deal with when stuff like this happens. It is really important for their business model to make returns and exchanges easy. That is why so many people shop Amazon.

-

Box what you received up and send it back and they'll refund your money.

-

https://www.shaftskinz.com/ https://shaftskins.com/ https://shaftwraps.com/ Im sure there are others as well.

-

What Is Your Next Planned Golf Equipment Purchase?

dbdors replied to GolfSpy_APH's topic in General Equipment Talk

I have a LAB DF3 on order, hope to have it at the end of April. Sold a bunch of unused gear and putters to pay for it. It better be good as this is the most Ive ever spent on a putter. I'm also planning on a Vessel Player IV Pro DXR 14-way for my birthday in June. -

Mizuno 221 4 iron possibly broken?

dbdors replied to PaladinGolf's topic in Club Making/Repair & DIY Projects

The shaft is bent. It will need to be replaced. -

I get that, but the fitting does not ask for a face on shot, down the line only.